In the rapidly evolving landscape of modern engineering and design, the relationship between physical materials and digital structures is increasingly intertwined. What once seemed like distinct domains—traditional materials such as wood, metal, and concrete versus digital architectures crafted through software—are now collaborating in revolutionary ways. This interconnectedness is not just a matter of aesthetics or convenience; it is shaping the very fundamentals of how we conceive, build, and interact with our environment.

This article explores the intricate interplay between classic materials and digital structures, examining how they foster each other and what this means for future innovation. We will delve into the unexpected links that bind tangible materials with virtual systems, outlining their impact on modern design, structural engineering, and beyond.

The Evolution of Material-Driven Digital Architectures

Historically, construction and design relied heavily on the properties of physical materials. For centuries, artisans and engineers learned to manipulate materials like stone, wood, brick, and metal to create enduring structures. These traditional materials possess inherent characteristics—strength, flexibility, durability—that directly influence the design possibilities.

With the advent of digital technology, particularly computer-aided design (CAD), Building Information Modeling (BIM), and parametric modeling, a new paradigm emerged. These tools enable architects and engineers to simulate, optimize, and virtually test structures before they are built, allowing for unprecedented precision and creativity.

But what is less recognized is how these digital tools are increasingly rooted in and inspired by the physical properties of traditional materials. For example, digital algorithms often mimic biological or natural patterns—such as the branching of trees or the cellular structure of bones—that are, in essence, reflections of material behavior and structural efficiency. This has led to digital structures that not only emulate physical materials but also expand upon them, creating hybrid forms that are optimized for both strength and aesthetic appeal.

The Reciprocal Relationship: Materials Influencing Digital Design

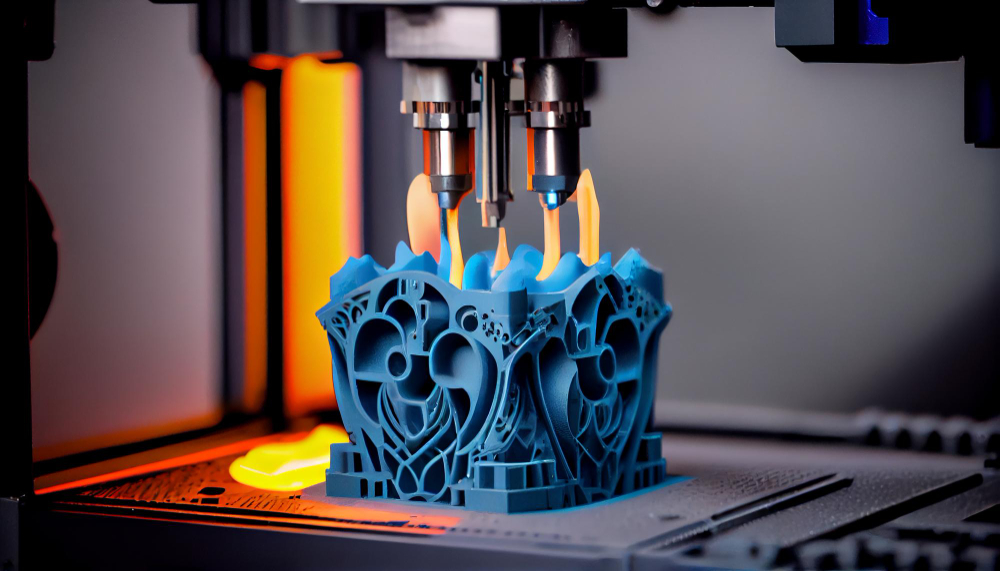

Surprisingly, traditional materials continue to influence digital design beyond mere inspiration. Advanced manufacturing techniques—like 3D printing and CNC machining—blurring the line between digital plans and physical objects. These methods allow designers to realize complex, organic forms that would be impossible—or prohibitively expensive—to produce through conventional means.

For instance, lattice structures derived from digital algorithms can be directly fabricated using metal or polymer 3D printing. These links between digital modeling and physical manufacturing create a feedback loop: the constraints and possibilities of materials inform digital designs, which in turn push material science forward as new forms and applications emerge.

Moreover, sensors embedded into physical structures—utilizing materials like fiber optics or smart polymers—translate real-world data into digital signals, establishing a dynamic dialogue between the physical and virtual realms. This integration facilitates real-time monitoring of structural health, environmental conditions, and user interaction, ensuring smarter, more adaptive structures.

Unexpected Synergies in Structural Engineering and Design

One of the most exciting developments arising from this material-digital synergy is the emergence of adaptive, responsive structures. These are architectural or infrastructural elements that can modify their shape, stiffness, or function in response to external stimuli. Such structures rely on smart materials—such as shape-memory alloys or piezoelectric elements—that are engineered with digital control systems.

Take, for example, bridges or buildings equipped with sensors and actuators that adjust their positioning or tension in real-time to accommodate shifting loads or environmental changes. This not only improves safety and longevity but also introduces a new aesthetic language—fluid, organic forms that evolve dynamically.

Similarly, digital fabrication techniques allow for the creation of intricate geometries inspired by the physical properties of materials. These complex forms are optimized for minimal material use while maximizing strength, leading to efficient, sustainable designs that meld traditional craftsmanship with cutting-edge technology.

Innovative Perspectives on Connecting Elements: Bridging the Gap Between Traditional Materials and Contemporary Digital Architectures to Uncover Unexpected Synergies and Future Possibilities in Structural Engineering and Design

The Promise of Material-Digital Symbiosis in the Future of Design

Looking ahead, the convergence of materials and digital structures promises transformative impacts across several fields. Here are some compelling prospects:

- Bio-inspired Materials and Structures: Drawing inspiration from nature, designers are experimenting with materials that adapt, heal, or respond to environmental stimuli. Combining these smart materials with digital modeling and control systems could yield self-healing infrastructure, materials that generate energy, or even structures that reconfigure themselves for different functions.

- Digital Material Fabrication: Advances in digital fabrication are enabling the production of complex, multi-material composite structures. Such integrated systems can combine rigidity with flexibility, conductivity with insulative properties, or aesthetic variation with structural integrity—all managed through digital software.

- Sustainable and Resilient Infrastructure: Using sensors embedded in traditional materials such as concrete or timber, structures can be monitored and maintained proactively. Digital twins—virtual replicas of physical structures—allow for simulation, diagnosis, and optimization, reducing waste and extending lifespan.

- Human-Centered Design and Interaction: As structures become “smarter,” their physical materials can serve as interfaces for human interaction. Touch-sensitive walls or floors made from conductive materials enable new modes of communication between people and their environment, blurring the line between physical and digital spaces.

Challenging Conventional Boundaries

The evolving landscape challenges conventional assumptions—that materials are static and digital systems are separate entities. Instead, it suggests a future where they become interconnected elements of a unified ecosystem. This shift encourages interdisciplinary collaboration among material scientists, digital designers, architects, and engineers.

For example, the development of programmable matter—materials whose properties can be dynamically altered by digital commands—is opening new horizons in construction and product design. Imagine walls that morph their configuration, floors that change texture, or furniture that reconfigures itself—taught through digital interfaces and made possible by advanced materials.

Conclusion

The unexpected links between classic materials and digital structures reveal a profound paradigm shift—one that marries the physical with the virtual in unprecedented ways. From bio-inspired structural optimization to adaptive, intelligent infrastructures, this symbiosis is redefining the boundaries of design and engineering.

The future holds remarkable promise: structures that are not only inspired by but also interact with their environment in dynamic, responsive ways. As we deepen our understanding of materials and harness the power of digital technology, the potential for innovative, sustainable, and human-centric design continues to grow. The ongoing interplay between physical materials and digital architectures is reshaping our built environment—crafted through a new language of interconnected, intelligent, and adaptable connecting elements.